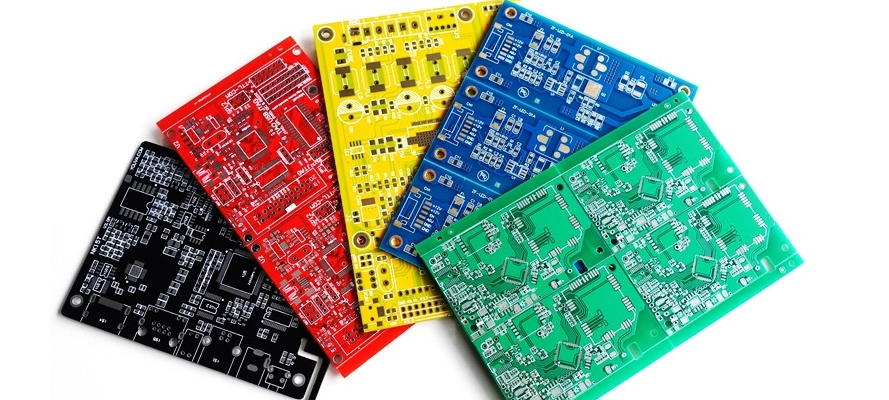

Top PCB Prototype Services for Innovator

Date: 2024-11-07 Categories: Blogs Hits: 334

In the fast-paced world of technology, the demand for high-quality Printed Circuit Board (PCB) prototypes has surged. As innovators, engineers, and entrepreneurs seek to transform their concepts into tangible products, understanding the best PCB prototype services available is essential. This comprehensive guide will explore the leading PCB prototype services, provide authoritative data, and highlight what you should consider when choosing a service provider.

The Importance of PCB Prototypes

PCB prototypes are a critical part of development. They help you verify your design before you move on to production.

Cost Efficiency

Statista said the cost of the prototype is usually 15% of the final product cost for the average product. So, just with the average product,you can avoid up to 50% of the $270,000 from the previous example by developing a prototype. A mistake on a simple design like this could be very costly.

Speed to Market

Speed to market is always a huge factor. The quicker you can get something in your customer’s hands, the greater the advantage you have over your competitors. So, there’s a lot of profit to be made by manufacturing quickly.

Design Validation

Validation through prototype is your only realistic method of designing your product for success. How can you verify the performance of your product? You could theoretically test your entire design for function, reliability, current carrying capacity, high-temperature reliability, and electrical performance. Many tests either must be completed on a physical product or can be verified through simulation first.

Risk Management

Early identification of design flaws helps mitigate the risk of product failure. According to the Project Management Institute (PMI), organizations that prioritize prototyping have a 30% lower project failure rate. Investing in reliable prototyping services not only helps avoid costly production losses but also safeguards the company’s reputation, enhancing market competitiveness.

Choosing the Right PCB Prototype Service

When selecting PCB prototype services, several key factors need to be considered:

1. Quality and Reliability

Choose suppliers with a solid reputation by reviewing customer feedback, success stories, and industry certifications (e.g., ISO 9001, IPC-A-610). For example, Advanced Circuits is trusted by many clients due to its rigorous quality control processes.

2. Production Capability

Ensure that the service provider can handle the complexity of the PCBs you need. This includes considerations like layer count, size, materials, and special functions (e.g., multi-layer circuits, miniaturization). Understanding a provider’s equipment and technical capabilities will help you assess whether they can meet the specific requirements of your project.

3. Customer Support and Technical Services

High-quality customer support is crucial for addressing issues that arise during the design and production phases. Look for suppliers that offer technical support, design reviews, and problem-solving services. PCBWay, for example, is known for its experienced technical team that provides real-time assistance to customers.

4. Delivery Time and Flexibility

Look for fast delivery.Contact your prospective partners and ask for delivery times.Can they easily accommodate rush delivery needs?What about emergency needs?

5. Transparent Pricing

Compare pricing structures between service providers to ensure there are no hidden fees. Understand what each quote includes, such as raw materials, processing, assembly, and shipping costs. Choose suppliers who provide detailed quotes and can clearly explain the cost breakdown to ensure budget control.

6. Technical Support and Engineering Consulting

In addition to production capability and delivery times, strong technical support and engineering consulting services are also crucial when selecting PCB prototype services. Many customers encounter complex technical issues during the design and manufacturing process, and a supplier that offers expert technical support can help solve these problems efficiently and optimize the product design. The key features of technical support are:

1. Design Validation and Optimization

Some PCB prototype manufacturers offer design validation services, analyzing your design files to identify potential design flaws or optimization opportunities. These validation services often include signal integrity analysis, power integrity analysis, thermal analysis, and electromagnetic compatibility (EMC) testing. This helps ensure that any design issues are addressed before mass production begins.

For example, some high-end PCB providers offer Gerber file review to ensure that your design complies with manufacturing requirements, preventing functional issues caused by manufacturing errors. Industry research shows that PCB design flaws are one of the leading causes of product failure, and early-stage optimization can significantly improve product quality.

2. Engineering Consulting

Specialize in engineering solutions. While your clients will not always have this level of technical expertise available, your firm can bring this added-value knowledge to your client to help their design perform as expected.

3. Fast Response and Technical Support

The good news is most PCB prototype service houses have some technicians and degreed engineers on staff already! However, they often forget to use these high-quality resources to address front-end discussions with customers. These pros are usually technical people looking to help customers, so encourage them to provide information at the beginning of the project.

4. Collaborative Work and Customization Services

Employ competent professionals who are familiar with current technologies and applications. Then use these people to help your PCB customers. Present technical information about what you can do to aid your customers to provide a better- finished product.

To serve your prototyping customers, understand the minimum volume of projects you execute before you collect different results at an off-the-shelf price.

5. Prototype Iteration and Revision

PCB prototyping often requires multiple iterations, especially when initial designs do not fully meet functional requirements. Providers that support prototype revisions and iterative updates will help customers quickly modify designs and test new versions until the final PCB design meets all specifications. Selecting a supplier that can quickly respond to revision requests and conduct multiple prototype tests within a short time frame can significantly accelerate the product development process.

Key Criteria for Choosing PCB Prototype Services

When selecting a PCB prototype service provider, businesses should focus on the following criteria to ensure that the service aligns with their specific needs and quality standards.

Selection Criteria Key Considerations Impact Quality Control ISO certifications, industry standards Ensures PCB prototypes meet design and functionality requirements Production Capability Layer count, size, materials, technical ability Meets complex design needs, ensuring project success Customer Support & Technical Services Real-time support, design review Addresses design and production issues, improving efficiency Delivery Time & Flexibility Standard delivery times, expedited services Ensures timely market responsiveness Transparent Pricing Pricing structure, hidden fees Optimizes budget control and reduces unnecessary costs Technical Support & Engineering Consulting Design validation, engineering consulting, fast response Provides expert support to optimize product design and accelerate development Interactive Platform Online ordering, order tracking Enhances user experience with transparency and convenience

Key Trends in PCB Prototyping

The PCB prototyping industry is evolving rapidly, and here are some key trends:

1. Manufacturing Automation

The first trend driving the printed circuit board industry is automation. One of the driving forces is the need for design assessments and calculations completed automatically. Before you can automate an excellent engineering assessment, several knowledge steps must occur. The odds show your potential customer will not be in a competitive market for printed circuit board prototyping today or in the near future.

2. Use of Advanced Materials

Paumanok’s study on rigid PCB laminates in the world market shows an expected growth at three percent per year over the next decade. However, it’s a different story for exotic high-performance materials. Expectations for these substrates include continued steady demand increases due to equipment enhancements and refinements in designs.

This market has a projected growth rate for flexible printed circuit boards of $20 billion of 10 percent per year until 2025.

3. Increased Environmental Awareness

Sustainability is another rising trend in the PCB industry. More companies are making their products with environmentally friendly methods. It’s becoming increasingly important for companies to adopt more sustainable manufacturing methods.

4. Integration with IoT

With the rapid growth of IoT devices, PCB prototypes must support various sensor and connectivity options. This trend is driving innovation in both design and manufacturing processes, with businesses needing to create PCBs that integrate seamlessly with IoT ecosystems.

5. Growing Demand for Customization

A growing demand for personalized designs. Companies are competing to find ways to create solutions for specific clients at a targeted price range.

Conclusion

Companies that choose to go the cheaper/bargain route make this decision consciously. When these folks contact you, you’ll know you will have limited ability to help them until they get to the point of choosing a vendor for quantity production. They will come to you when they realize the low-cost prototype circuit board they used for their project to save a few hundred dollars is not available for the million part order at the same price.

Investing in PCB prototyping services enables you to move through the development cycle quicker and launch your new product effectively. When you understand this process and the trends involved, you can be on the leading edge of the new opportunities in the PCB prototyping market.

With the right partner, you’ll be able to bring your product design and production to life quickly and efficiently.

Take the Next Step

Elevate your electronic products by partnering with Huaxing. Contact us today to discover how our expertise in PCB manufacturing and assembly can drive your business forward.

Phone: 86-755-23146369

Website: www.uppcba.com

Recommended reading

1.Essential PCB Testing Equipment for Accurate Results

2.A Comprehensive Guide to PCB Prototyping and EMS PCBA Services

3.3D Printing PCB vs. Traditional PCB Manufacturing