Top notch pcb assembly huaxing delivers 20 years of expertise

Date: 2024-11-28 Categories: Blogs Hits: 179

Why Quality in PCB Assembly Matters

Think about the last time you used your smartphone, turned on your washing machine, or jumped into your car. Inside all of these devices is a printed circuit board (PCB)—the unsung hero that connects all the components together and makes everything function as it should. The accuracy of the PCB assembly process is absolutely critical to the performance of these devices. After all, no one wants a smartphone that freezes, a car that doesn’t start, or an appliance that doesn’t perform as expected.

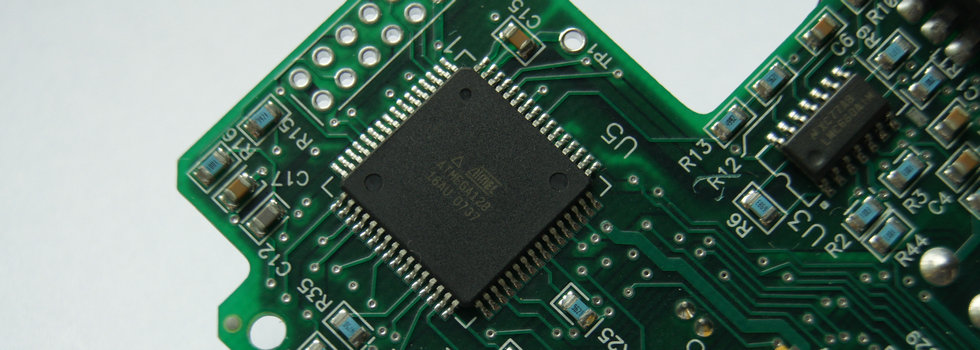

PCB assembly (PCBA) is the meticulous process of attaching and soldering components—everything from microchips to connectors—onto a PCB to make it work according to design specifications. This isn’t just about putting pieces together; it requires a high level of precision and the ability to meet rigorous quality standards. Even the smallest misalignment, an incorrect solder joint, or a failed test can turn a perfectly good design into a malfunctioning product. This can lead to costly returns, damaged reputations, and frustrating customer experiences.

At Huaxing, we understand how important this process is. Our commitment to high-quality assembly ensures that every board we produce is flawless, reliable, and ready to perform in the real world.

The Challenges of Modern PCB Assembly

As technology advances, the demands on PCB assembly grow. The trend toward smaller, smarter, and more powerful devices presents unique challenges for manufacturers. Today’s devices are more compact, yet more complex, with tightly packed components that must be assembled with pinpoint accuracy.

Take, for example, wearables, electric vehicles, and industrial sensors—these devices require cutting-edge PCB designs and assembly techniques. To meet these demands, PCBs need to shrink in size while supporting increasingly sophisticated and miniaturized components. This is where Surface Mount Technology (SMT) comes in. SMT allows for incredibly small components to be placed onto a PCB with high precision, making it the go-to solution for today’s high-performance electronics.

At HuaXing, we’ve invested in the latest SMT technology, ensuring that we can handle even the most compact and intricate designs. Whether it’s a tiny wearable sensor or a high-performance automotive system, our advanced machines and expert team guarantee that your products are built with the utmost care and precision.

How to Choose the Right PCB Assembly Partner

When it comes to selecting a PCB assembly partner, experience, capabilities, and customer service are paramount. You want a partner who not only understands the technical challenges of PCB assembly but who also knows how to turn your vision into reality. Here’s what to look for:

1. Experience and Industry Knowledge

Experience counts in PCB assembly. A provider with years of experience knows how to navigate the challenges of complex designs and stringent industry standards. At Huaxing, we’ve been serving clients across a variety of industries for over 20 years. From consumer electronics to automotive and industrial systems, we’ve developed a reputation for delivering results that exceed expectations. Our deep industry knowledge ensures that we can handle your unique needs with confidence.

2. Comprehensive PCB Assembly Services

A great PCB assembly partner offers more than just assembly—they provide end-to-end solutions to make your life easier. At Huaxing, we offer a comprehensive range of services to support your project at every stage, including:

Design Assistance: Our team works closely with you from the very beginning to optimize PCB designs for performance, manufacturability, and cost-efficiency.

Rapid Prototyping: Test your designs quickly and effectively with our fast prototyping services. We help you iron out potential issues before moving to full-scale production.

Advanced Assembly: We offer both Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly, ensuring we can handle a wide variety of designs and requirements.

Testing & Quality Assurance: We conduct comprehensive testing, including Automated Optical Inspection (AOI), X-Ray Analysis, and Functional Testing, to ensure every PCB meets the highest quality standards.

3. Investment in Advanced Technology

The PCB assembly industry is evolving rapidly, and staying ahead of the curve requires continual investment in the latest technologies. Huaxing’s commitment to innovation means that we’re always upgrading our equipment and techniques to stay on the cutting edge. Some of the advanced technologies we use include:

High-Precision SMT Equipment: For even the smallest and most complex components, ensuring perfect placement and soldering.

X-Ray Inspection Systems: These allow us to inspect multilayer boards and detect hidden solder joints that could cause issues down the line.

Automated Testing Systems: We use sophisticated testing systems to conduct thorough checks of every board, identifying any issues before they reach you.

The Global PCB Assembly Market: Trends and Insights

The PCB assembly market is growing at an impressive rate, driven by rapid advancements in industries such as consumer electronics, automotive systems, and the Internet of Things (IoT). As devices become smarter, more connected, and more powerful, the need for high-quality, reliable PCB assemblies is greater than ever. Here’s a look at the market’s growth trajectory:

| Year | Market Size (USD Billion) | Growth Rate (%) | Key Growth Drivers |

|---|---|---|---|

| 2020 | 65.2 | 3.5 | Growth in consumer electronics and IoT |

| 2022 | 75.8 | 7.2 | Expansion in automotive electronics and ADAS (Advanced Driver Assistance Systems) |

| 2025* | 100.3 | 8.5 | Demand for AI, 5G, and electric vehicles |

| 2030* | 130.4 | 6.0 | Adoption of smart devices and green energy |

(*Forecast based on current trends)

How HuaXing Tackles Industry Challenges

While the PCB assembly industry faces some tough challenges, Huaxing is always ready to rise to the occasion. Here’s how we tackle the most common obstacles in the field:

1. Component Miniaturization

As technology advances, components get smaller and more densely packed. Our advanced SMT equipment ensures precise placement even for the tiniest components, guaranteeing flawless assemblies every time.

2. On-Time Delivery

We understand the importance of deadlines, especially in industries where time-to-market is critical. Our streamlined production processes, combined with rapid prototyping and agile manufacturing methods, allow us to deliver on-time, every time.

3. Meeting Unique Client Needs

Every project is different. That’s why we work closely with each client to understand their unique requirements—whether it’s a specific testing protocol, a tight deadline, or custom design specifications. We’re flexible and responsive, always ready to adapt to your needs.

4. Consistent Quality

You can’t afford to cut corners when it comes to quality. At Huaxing, we maintain strict quality control at every stage of production, from design to final testing, to ensure every PCB is up to standard. Our dedication to quality has earned us the trust of clients worldwide.

Why HuaXing?

Customer-Centric Approach: We work hand-in-hand with you, offering customized solutions to meet your unique needs.

Competitive Pricing: Get high-quality PCB assembly at prices that make sense for your business.

Global Reach: With clients across North America, Europe, and Asia, we’re ready to support your global projects.

Sustainability: We adhere to RoHS environmental standards, ensuring that our manufacturing processes are eco-friendly and compliant.

Case Study: Success in the Automotive Sector

Background:

A leading automotive electronics manufacturer approached Huaxing to assemble PCBs for their ADAS (Advanced Driver Assistance System) module.

Challenges:

Strict project deadlines tied to an upcoming vehicle launch.

High component density and complex environmental performance requirements.

Our Solution:

Close collaboration with the client’s design team to optimize PCB layouts for manufacturability and performance.

Use of high-precision SMT equipment to handle the dense, complex component placements.

Rigorous environmental stress testing to ensure the PCBs could withstand extreme conditions.

Results:

We delivered the project ahead of schedule, with zero defects during testing, allowing the client to successfully launch their product on time.

Looking to the Future: Why HuaXing?

As the demand for next-generation electronics continues to grow, Huaxing is dedicated to staying at the forefront of the PCB assembly industry. Our commitment to innovation, quality, and customer satisfaction makes us the ideal partner for your PCB needs. Whether you’re building the latest consumer electronics, designing the next big IoT device, or developing critical automotive systems, Huaxing has the expertise, technology, and experience to help you succeed.

Choose Huaxing for your PCB assembly needs and experience the difference in quality, service, and reliability.

Contact us today and let’s bring your vision to life!

Take the Next Step

Elevate your electronic products by partnering with Huaxing. Contact us today to discover how our expertise in PCB manufacturing and assembly can drive your business forward.

Phone: 86-755-23146369

Website: www.uppcba.com

Recommended reading

1.Essential PCB Testing Equipment for Accurate Results

2.The Ultimate Guide to PCB and PCBA Manufacturing

3.Why Choosing a PCB Manufacturer in China