PCB vs. PCBA: Which One Do You Need for Your Project?

Date: 2024-12-12 Categories: Blogs Hits: 821

In the fast-paced world of electronics manufacturing, the terms Printed Circuit Board (PCB) and Printed Circuit Board Assembly (PCBA) are often used interchangeably, but they refer to very different things. Both are essential to modern electronics, yet their applications, costs, and stages of production are distinct. Choosing between a PCB and a PCBA for your project is not just a matter of terminology—it’s about understanding the purpose and requirements of your device at its specific stage of development.

This guide will dive deep into what sets PCBs and PCBAs apart, explore their applications across industries, and provide insights backed by authoritative data. By the end, you’ll have a clear understanding of when to use a PCB, when to opt for a PCBA, and how to choose the right manufacturing partner.

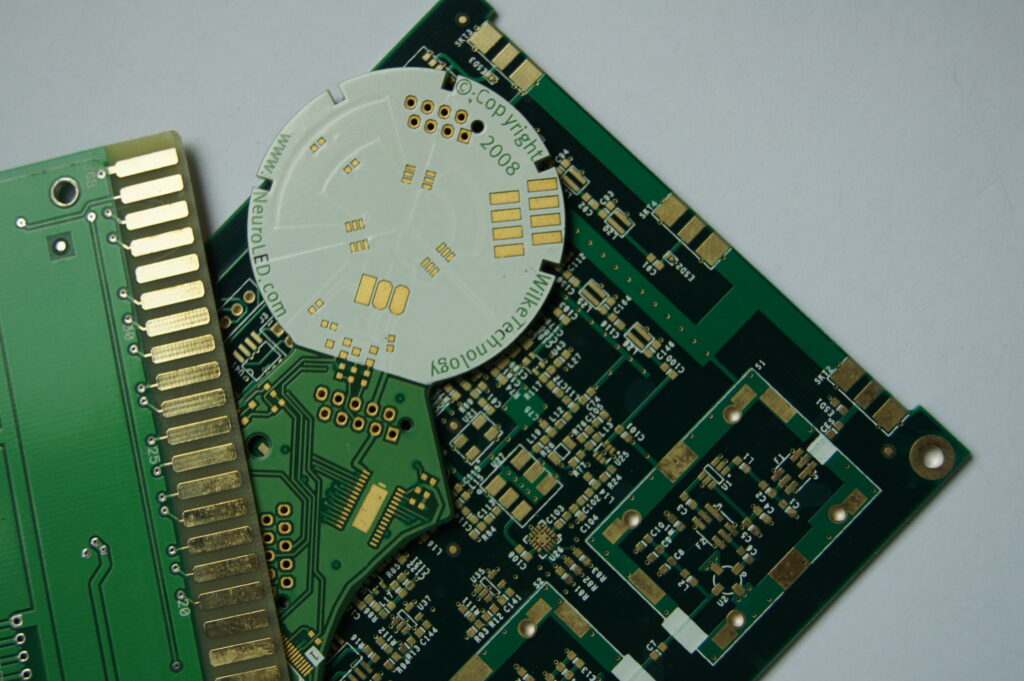

What is a PCB?

A Printed Circuit Board (PCB) is a flat, rigid structure that mechanically supports and electrically connects electronic components. PCBs are made from a non-conductive base material, usually fiberglass (FR4), with conductive copper traces etched onto one or both sides.

Structure and Composition of PCBs

PCBs come in various configurations depending on the complexity of the circuit:

Single-Sided PCBs: These have copper traces on only one side and are used in simple devices like calculators.

Double-Sided PCBs: Traces on both sides allow for more complex circuits.

Multi-Layer PCBs: These are built with multiple layers of conductive material, separated by insulating layers, and are used in advanced applications such as smartphones and medical devices.

Types of PCBs by Application

1.Rigid PCBs: Common in consumer electronics.

2.Flexible PCBs: Used in wearable devices and compact electronics.

3.Rigid-Flex PCBs: Found in aerospace and medical equipment for their durability and space efficiency.

4.High-Frequency PCBs: Designed for telecommunications and radar systems.

Advantages of PCBs

Compact and lightweight.

Cost-effective for large-scale production.

Excellent reliability due to automated manufacturing processes.

What is a PCBA?

A Printed Circuit Board Assembly (PCBA) refers to a PCB that has been populated with electronic components, such as resistors, capacitors, integrated circuits (ICs), and connectors. A PCBA is essentially the functional version of a PCB, ready to perform specific tasks.

Key Components of a PCBA

Active Components: Such as transistors, diodes, and ICs that perform critical functions like amplification, computation, and data storage.

Passive Components: Including resistors and capacitors that support the circuit’s functionality.

Connectors: Allow the PCBA to interface with other systems or devices.

Advantages of PCBAs

Fully functional and tested, making them ready for integration into devices.

Built with precision using automated pick-and-place machines.

Enhanced reliability due to rigorous testing during assembly.

PCB vs. PCBA: A Detailed Comparison

To clarify the distinctions between PCBs and PCBAs, the following table summarizes their key differences:

| Aspect | PCB | PCBA |

|---|---|---|

| Definition | A bare board with conductive traces. | A PCB with components mounted and soldered. |

| Components | None | Resistors, capacitors, ICs, and connectors. |

| Production Stage | Early stage in the manufacturing process. | Final stage, after component assembly. |

| Testing | No functional testing needed. | Undergoes functional and in-circuit testing. |

| Cost | Lower due to lack of components. | Higher due to component costs and assembly. |

| Applications | Prototypes and design verification. | Finished products ready for deployment. |

Applications and Use Cases

Understanding when to use a PCB or a PCBA depends on the specific stage of your project and its requirements. Let’s explore their applications across industries:

Applications of PCBs

Prototyping: PCBs are commonly used during the initial design phase to test layouts and trace designs.

Simple Devices: Ideal for low-cost, low-complexity devices such as toys or basic consumer electronics.

DIY Projects: Hobbyists often use PCBs for small-scale personal projects.

Applications of PCBAs

Consumer Electronics: Found in smartphones, laptops, and smart home devices where functionality is critical.

Industrial Automation: PCBAs power robots, PLCs, and sensors used in automated systems.

Healthcare: Essential in advanced diagnostic tools, monitoring devices, and surgical equipment.

Aerospace: Provide reliability and performance in avionics and communication systems.

The Manufacturing Process

PCB Manufacturing Steps

1.Design and Layout: Engineers use CAD software to create the board’s layout.

2.Material Selection: Fiberglass or other materials are chosen based on the application.

3.Etching: Copper layers are chemically etched to create traces.

4.Drilling: Holes for vias and through-hole components are drilled with high precision.

5.Finishing: Surface finishes like ENIG (Electroless Nickel Immersion Gold) are applied for durability.

6.Testing: Optical and mechanical inspections ensure the board matches design specifications.

PCBA Manufacturing Steps

1.Component Sourcing: Components are procured based on the Bill of Materials (BOM).

2.Solder Paste Application: Solder paste is applied to the PCB where components will be mounted.

3.Pick-and-Place Assembly: Components are placed on the board using automated machines.

4.Reflow Soldering: The board is heated to melt solder, securing components.

5.Inspection: Automated Optical Inspection (AOI) checks for assembly errors.

6.Functional Testing: Ensures the PCBA operates as intended under simulated conditions.

Market Insights

The global demand for PCBs and PCBAs continues to grow, fueled by innovations in technology and increasing adoption of smart devices. According to recent industry reports:

The global PCB market was valued at $60 billion in 2023 and is projected to grow at a CAGR of 4.5%, reaching $75 billion by 2028.

The PCBA market is expanding faster, with a CAGR of 6.7%, driven by industries like IoT, automotive, and renewable energy.

Factors to Consider When Choosing a Manufacturer

Selecting the right manufacturer is crucial to the success of your project. Here’s what to look for:

1.Expertise and Experience: Choose a partner with a strong track record in your industry.

2.Technological Capabilities: Ensure they can handle advanced requirements like HDI or rigid-flex boards.

3.Quality Assurance: Look for robust testing processes, including AOI, X-ray inspection, and functional testing.

4.Scalability: Opt for a manufacturer who can scale production as your business grows.

5.Cost Efficiency: Find a balance between competitive pricing and high quality.

PCB and PCBA Costs: A Breakdown

Understanding the cost structure of PCBs and PCBAs can help you budget effectively.

Cost Factors for PCBs

Material Costs: Substrates like FR4 are cheaper, while high-performance materials like ceramic are more expensive.

Layer Count: Single-layer boards are the most affordable, while multi-layer and HDI boards increase costs significantly.

Surface Finishes: ENIG and HASL finishes differ in cost but affect durability and solderability.

Cost Factors for PCBAs

Component Costs: Prices vary based on the BOM, component availability, and market conditions.

Assembly Costs: Automated assembly is more cost-effective for large volumes, while manual assembly is better for small runs.

Testing and QA: High-quality testing adds costs but ensures reliability.

Conclusion

Deciding between PCBs and PCBAs depends on your project stage and requirements. PCBs are ideal for prototyping and structural foundations, while PCBAs are necessary for fully functional devices ready for deployment.

At Huaxing, we’ve been manufacturing high-quality PCBs and PCBAs for years, serving diverse industries with precision and reliability. Whether you’re prototyping or scaling production, we provide tailored solutions to meet your needs.

Get in Touch Today

Ready to take your project to the next level? Contact Huaxing for expert guidance, competitive pricing, and top-tier manufacturing services.

Take the Next Step

Elevate your electronic products by partnering with Huaxing. Contact us today to discover how our expertise in PCB manufacturing and assembly can drive your business forward.

Phone: 86-755-23146369

Website: www.uppcba.com

Recommended reading

1.Top notch pcb assembly huaxing delivers 20 years of expertis